Schroeder Folding Machines

Press brakes are inaccurate, labour-intensive, dangerous and heavily dependent on skilled operators.

This makes bending the most challenging part of sheet-metal processing. Productivity drops as part size grows, and errors cascade through every downstream operation, driving up costs and creating bottlenecks.

Schroeder folders change the game 180 degrees: with over 90% of handling machine-controlled and consistently built-in pinpoint accuracy, Schroeder folders eliminate size constraints, reduce operator influence, and drastically clean up downstream operations.

The result is faster production, greater flexibility, fewer errors, lower costs, and a bending process that finally works for you—not against you.

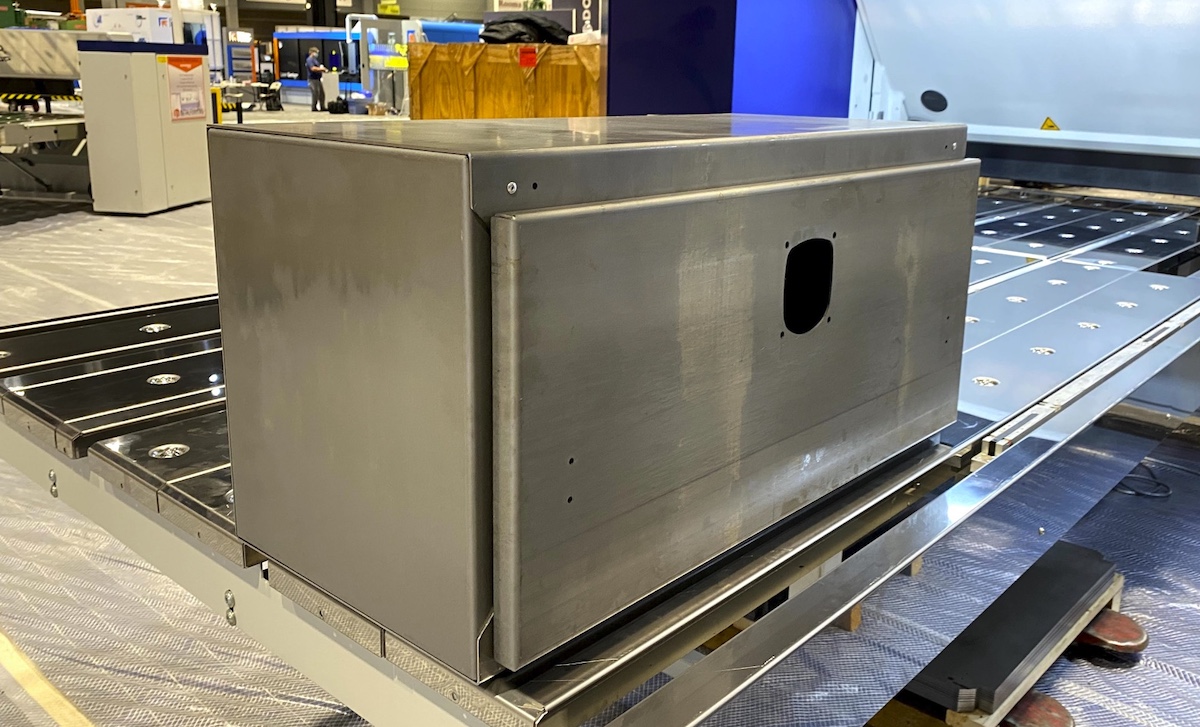

- Folder parts are perfect for laser welding—crisp, precise, ready.

- From simple profiles to complex enclosures—all consistently high-accuracy.

- Over 90% machine-controlled—minimal errors, no fatigue, no extra staff.

- Large parts? No slowdown. Steady throughput all day.

- ATC models: any part, any time, almost zero setup.

- Eliminates downstream headaches in welding, finishing, assembly.

- Ergonomic, sustainable, fully efficient.

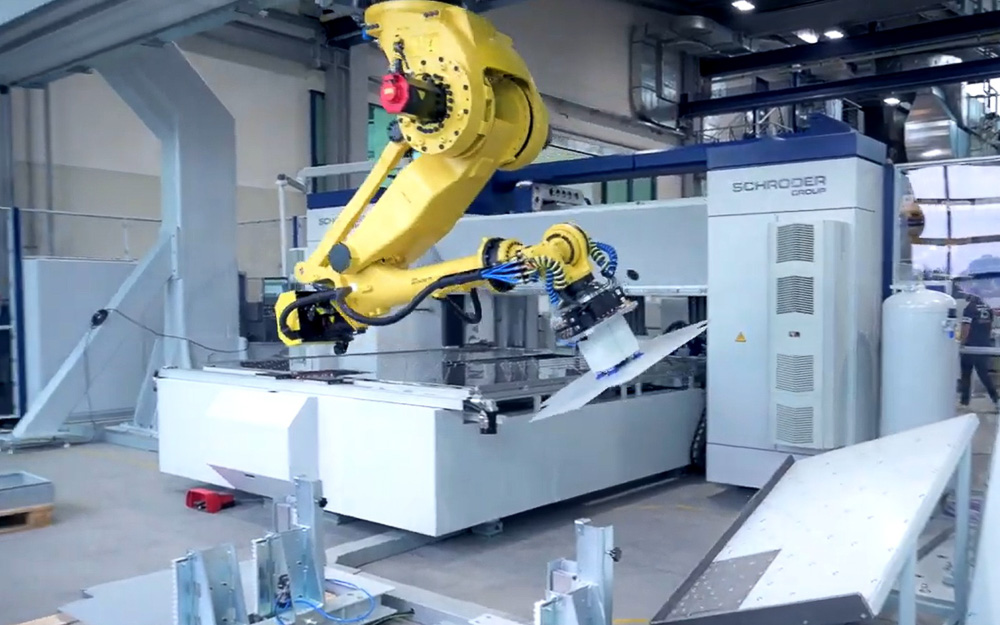

- From semi-auto to fully integrated lines.

- Major OEMs start demanding folder-made parts from their Tier 1 suppliers.

- There is no viable alternative today.

Benchmark capacities for up-down bending machines

- Max thickness: ¼” mild steel at 10 ft length

- Max bending length 198” at 157” thickness

- Benchmark capacities for up bending machines:

- Max thickness: 5/8” mild steel at 10 ft length

Download Schroeder Group PDF Brochure

Download Overview PDF Folder-Parts

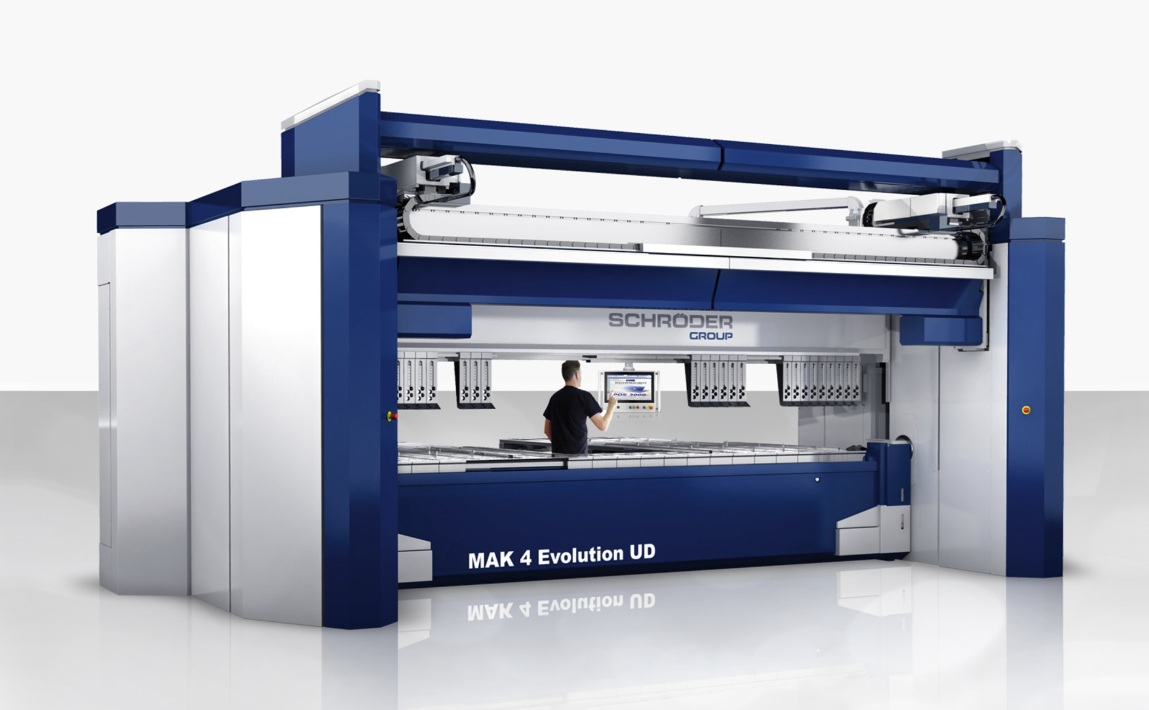

EVO Mak-4

- Click for Video

EVO Automation

- Click for Video

EVO Duobend

- Click for Video

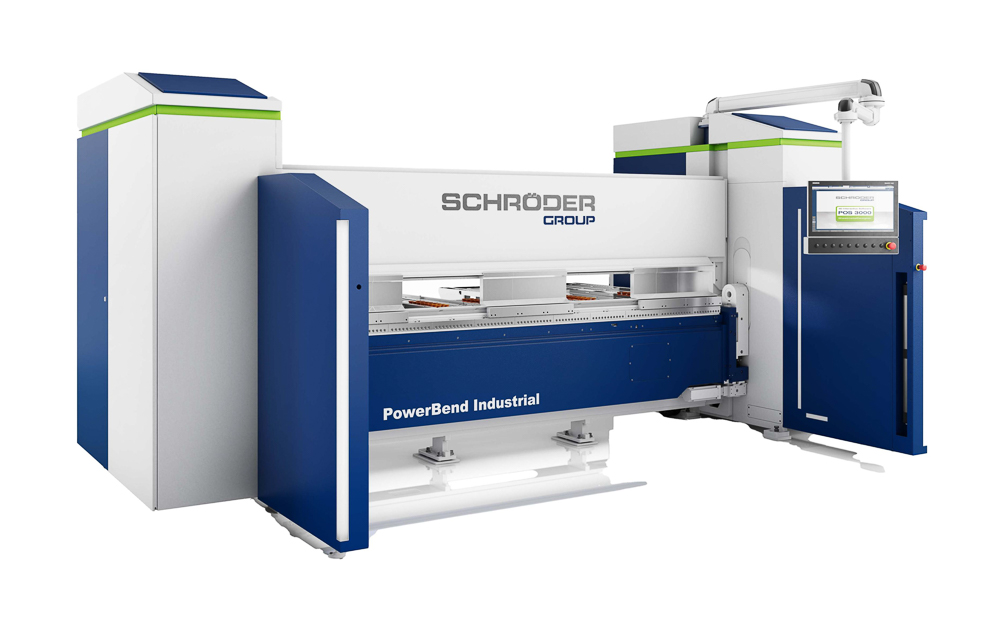

Powerbend Industrial

- Click for Video

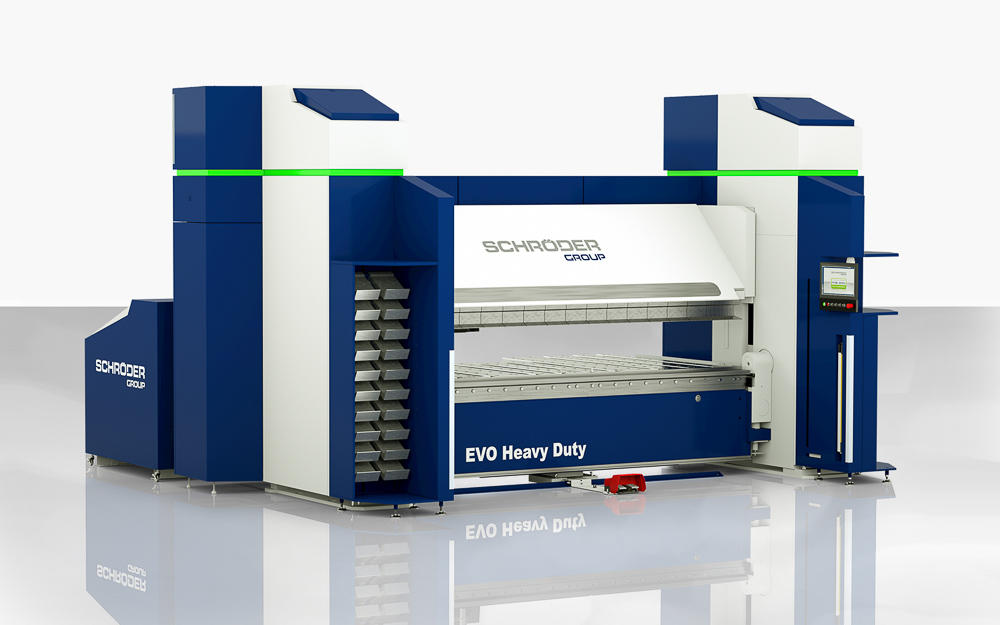

Heavy Duty

- Click for Video

Evo-Center

- Click for Video

Contact us for your next machine project

I pick up the phone myself for a real conversation.

Schroeder Import and Service for North America is done by MetalForming LLC in GA USA